Spark Plug Igniter

Commercial and military travel to the upper atmosphere will become more common over the next decades. Increased travel back into the atmosphere will demand higher ignition system reliability of SPARK PLUG CERAMIC TO METAL BRAZING DESIGN CONSDIERATIONS

engines directing vehicles safely back to Earth.

MCBS provides precision metalization and brazing expertise for the space and aerospace industries, partnering with suppliers to develop spark ignition system components. MCBS considers spark plug materials purity, thickness, and placement critical features for reliable ignition. Developing appropriate statistical methods for testing from research through the manufacturing processes are a key aspect of long term success.

Ceramic insulation and high purity Aluminum Oxide provide sufficient thermal conductivity and thermal expansion properties for most applications. Aluminum Oxide purity above 96% is a common requirement .

Precision coating thickness ensures the highest reliability for ongoing ignition performance. Coating thickness control provides consistency in the heat profile of the spark plug electrode, limiting wear and increasing firing temperature consistency

Modern design features which focus on fuel burn stability require exacting braze joint placement. Focused Quality Control across batches and production runs must be aligned to the specific design attribute requirements. In addition, inspection methods and quality acceptance limits must include consideration for variation in materials, inspection techniques, and application requirements.

Quality control starts in the research phase. Proper use of DOE and statistical methods provide the knowledge base which lead to a deeper process understanding and better design decisions. DOE results define the limits of successful operation. The operational limits are then translated into manufacturing and testing requirements. Test methods, process documentation, material variation, and material traceability must be carefully considered throughout the R&D phase.

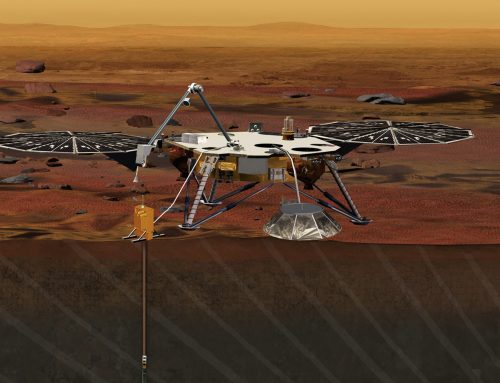

MBCS provides proprietary metalization and brazing techniques to solve critical performance under extreme conditions. MCBS is the trusted JPL/NASA supplier for brazing and metalization quality.

References:

1. “Modern Engineering for Design of Liquid-Propellant Rocket Engines”, Dieter Huzel and David Huang, Vol 147, Progress in Astronautics and Aeronautics, AIAA, 1992

2. “Future Igniter Technologies”, Welland and Bauers, Aerospace Propulsion Products

3. “The Rocket Files: 2nd Edition: A Comprehensive Guide to Rocketry”, Jimmerson, 2002, Lulu

4. NASA, https://www.nasa.gov/sites/default/files/images/662995main_upper-atmosphere-MOS_full.jpg

5. “Inside the LEO Doghouse: Light My Fire!“, NASA, Greene, 2014

6. “Coming Home: Reentry and Recover from Space”, Launius, NASA, 2011